Understanding Product Costs for Better Business Decisions

This cost can be used in several ways, either to report on the financial results of a business, or to make decisions about the viability of a product. Consequently, the accumulation of product costs forms a key element not only of an organization’s financial reporting, but also its management decision-making. Financial bookkeeping reporting involves compliance with accounting standards like GAAP and IFRS, guiding inventory valuation and cost capitalization.

Direct Labor Cost

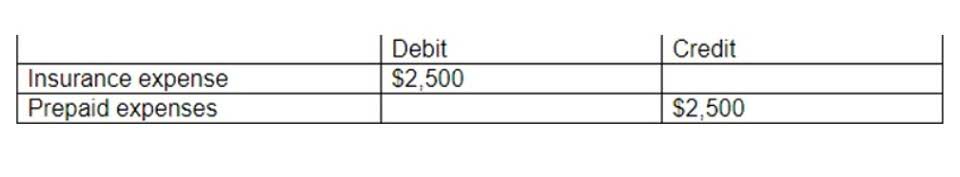

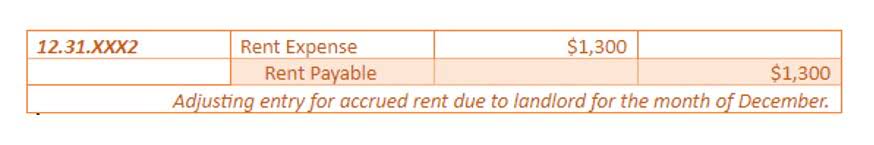

Expenses incurred to sell the finished inventory, on the other hand, are not considered product costs. For example, advertising costs and sales staff salaries are not necessary to produce the products. These expenses are considered period costs and are expensed in the period they are incurred. Similarly, salaries paid to office and administrative staff don’t contribute to the production of product. Thus, these too are considered period costs and reported on the income statement as an expense. Direct materials are easily identifiable and measurable raw materials directly transformed into the finished product.

What is included in Product Cost?

It should be a collaborative effort from executives, marketing, sales, product managers, and finance. Depending on the company, product managers may or may not determine the pricing strategy for the product. The most crucial step of the whole budgeting process is determining the overall and expected product cost per unit (shirt). Product cost management requires careful consideration of materials, labor, overhead expenses, research & development costs, marketing costs, and more. The cost of doing business can change over time, so reviewing your prices regularly is important.

- Knowing the risks allows you to decide whether or not to use this pricing strategy.

- All of these expenses are required in order to turn a raw material into a finished good.

- However, other indirect costs are more closely related to specific products or services.

- For the chair example, this would include the wood, nails, glue, and labor, among other costs.

- For example, John & Muller company manufactures 500 units of product X in year 2022.

Is Overcosting More Dangerous than Undercosting? If so, why?

Another way to reduce direct labor costs is to pay employees less per hour by either lowering wages or using cheaper labor sources. Direct Labor Is the pay you would give the workers who assemble the product. When it comes to pricing, many stakeholders have a say in how much a customer should pay for a product.

Shaun Conrad is a Certified Public Accountant and CPA exam expert with a passion for teaching. After almost a decade of experience in public accounting, he created MyAccountingCourse.com to help people learn accounting & finance, pass the CPA exam, and start their career. Discover the key to effective financial management with our straightforward guide on variance reporting. Product cost is one of the most important concepts in business manageent, standing as a cornerstone for effective decision-making. Incentives — bonuses to employees may still be less expensive than paying overtime and product costs consist of other staff expenses. Responsibility for effectiveness – increasing productivity through active performance management.

Direct material

Product costs include direct materials, direct labor, and overhead expenses. These costs are capitalized as inventory and become part of the cost of goods sold when the product is sold. Direct laborers are the employees or the labor force that gets directly involved in producing or manufacturing finished goods from raw materials. The direct labor costs are the salaries, wages, and benefits (like insurance) paid to these labor forces against their services.

Direct Materials Cost

- Direct Labor Is the pay you would give the workers who assemble the product.

- By improving product quality, manufacturers can reduce material costs while reducing warranty expenses and increasing customer satisfaction.

- Knowing the true costs of development can help you determine what features to build, whether for an MVP or for your next major update.

- When a company under costs its products, it may find itself in a situation where it cannot cover its costs and make a profit.

- Understanding how to properly categorize these costs helps you optimize your spending, prioritize investments, and ultimately, drive the company’s growth and success.

If you find that you’re regularly losing business because your rates are too high, it might be time Restaurant Cash Flow Management to consider lowering them. Still, no more material is available for purchase (and, therefore, must be ordered at an additional cost). These costs can be either fixed or variable depending on the type of product being manufactured. Fixed costs remain constant regardless of how much is produced, while variable costs vary based on production volume.

- Alternatively, customer research can show that you are on the wrong path and need to pivot.

- To avoid these problems, competitively pricing your goods and services is essential.

- Understanding the components of cost, how they are calculated, and how cost records should be maintained must be given the importance it deserves.

- The cost of 300 units would be transferred to cost of goods sold during the year 2022 which would appear on the income statement of 2022.

- The direct materials, direct labor and manufacturing overhead costs incurred to manufacture these 500 units would be initially recorded as inventory (i.e., an asset).

This can include wages, benefits, and any other expenses related to the employees who have the product. For example, if a carpenter makes the chair, the direct labor cost would include their wages and benefits. By considering these key points, businesses can gain valuable insights into their financial performance and make informed decisions about product cost accounting. By understanding their cost structure, businesses can better identify opportunities for improvement and make informed decisions about how to price products in the marketplace. The easiest and most popular way is to allocate costs by assigning a cost per unit, though this sounds easier than it is.

Product cost can be calculated by summing up all the direct costs (materials, labor) and indirect costs (overhead, administrative expenses) incurred in manufacturing a product. Accurate calculation and allocation of product costs impact financial reporting, influencing the balance sheet and income statement. Properly capitalized costs contribute to inventory valuation, affecting cost of goods sold and net income.